FENCING brings together top technology and is designed in strict accordance with international standards

In order to ensure that the product has a different weather resistance, our technology center has studied dozens of special surface treatment processes, the application of modern high-tech and multiple special process treatment ensure the product has excellent corrosion resistance, moisture resistance, weather resistance, and long-term surface self-cleaning ability. No matter in what kind of harsh environment, the guardrail will not rust, fade, crack, pulverize, aging, shed, etc. The color of the product is durable and bright, And we can completely eliminate the troubles caused by daily maintenance products.

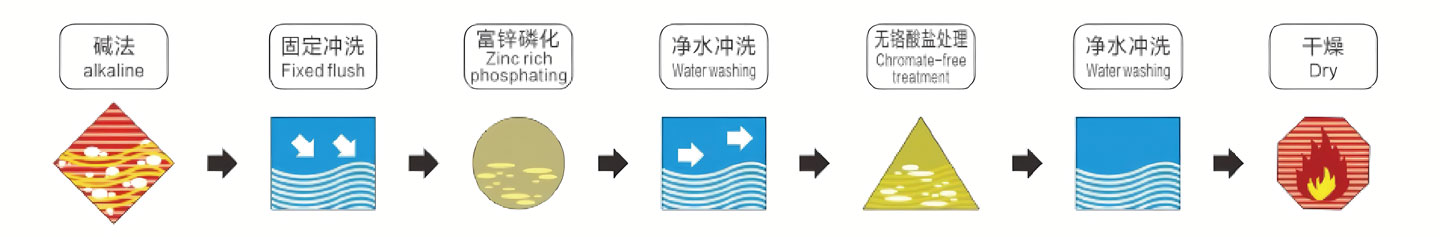

The metal surface's phosphate skin membrane treatment, refers to clean the metal surface at first, letting the metal and the prepared phosphating solution contact under specific conditions, and through chemical or electrochemical reaction, forming the phosphate skin membrane on the metal surface which is insoluble in water. Most of them are for the purpose of preventing metal rust (oxidation) and corrosion prevention. If there are fat, dirt and oxide skin on the surface, they can hinder the formation reaction of the membrane.The general process is: water washing (ash removal) a pickling alkali method (oil removal) - water washing - phosphating - water washing - passivation - drying.

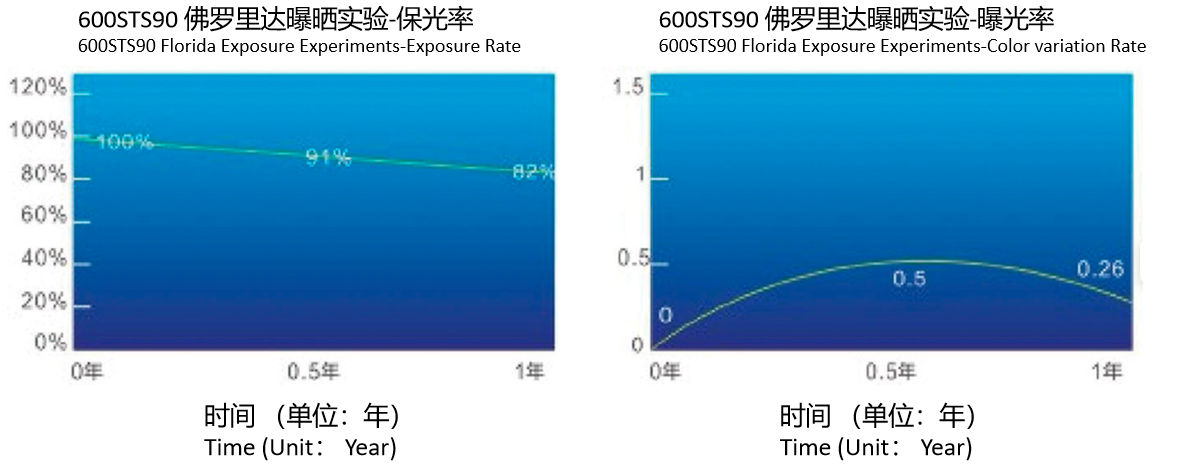

SUPERIOR UY PERFORMANCE

The results of long-term outdoor testing show that AkzoNobel's dual permanent coating is different from the fluidized-bed dipping process coating in terms of resistance to harmful UV corrosion.

EXCELLENT CORROSION RESISTANCE

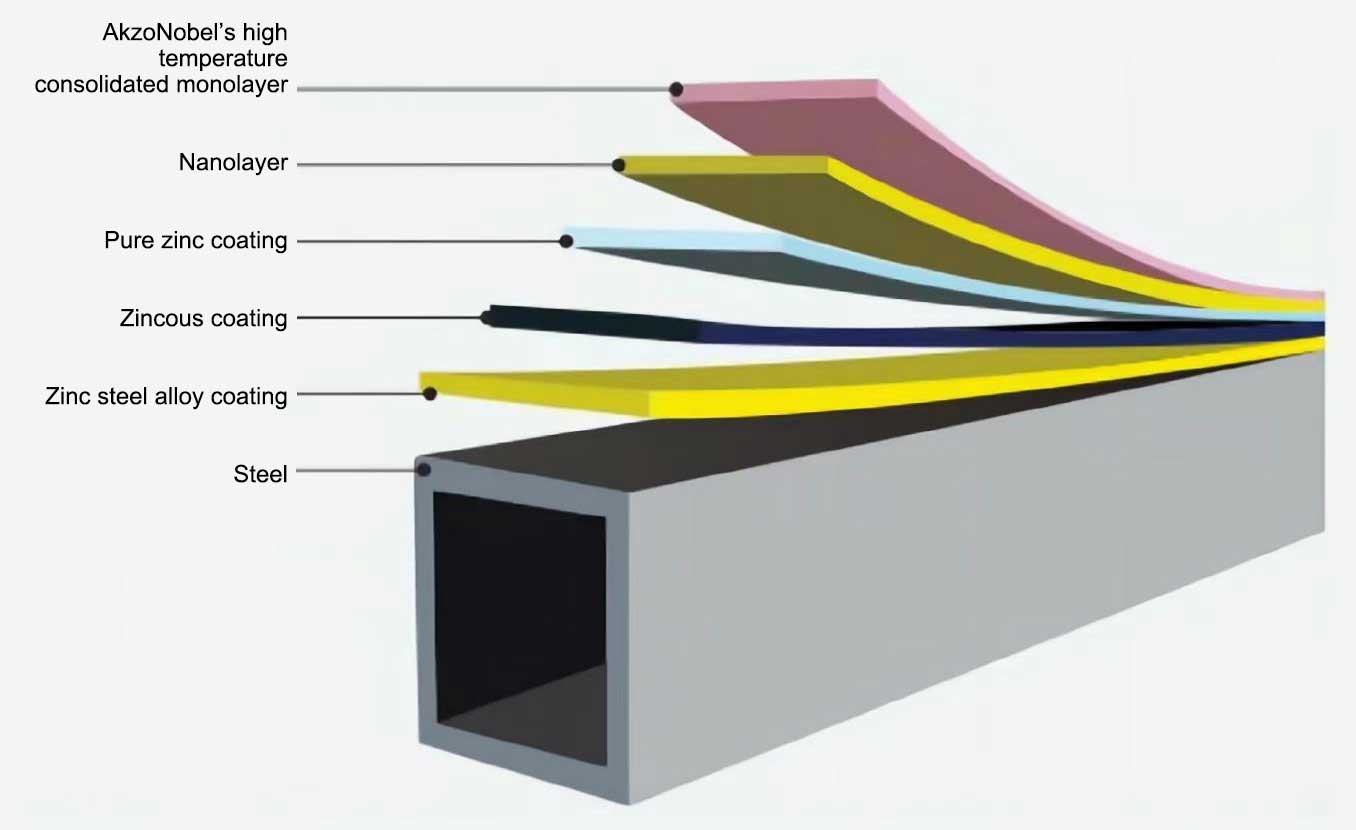

FENCING's zinc steel profiles adopt AkzoNobel's double permanent coating, polyurethane powder coating, which is superior to traditional coating processes such as paint and dip plastic in corrosion resistance. Professional imported anti-rust oil is selected to provide outdoor professional anti-rust protection. The metal surface can be covered by electrostatic spraying to make it have strong anti-rust properties.

Coating performance requirements:

| Feature | ASTM standard | Test results (mode) |

| Adhesive force | D3359 | Adhesion of 90% of coating in test area (cutting adhesive test) |

| Anti-corrosion property | B117 D1645 | Corrosion resistance 3500 hours (salt spray testing machine) |

| Impact resistance | D2794 | Impact resistance over 60 LBS/inch (pellet impact test) |

| Weather fastness | D822 D2244 D532 | Weather resistance of 1000 hours (outdoor environment test) |

6 STANDARD COLORS, CAN ALSO BE CUSTOMIZED ACCORDING TO THE PROJECT NEEDS

| Black RAL9005 | White RAL9016 | Grey RAL7031 |

| Blue RAL5017 | Green RAL6005 | Yellow RAL1023 |

* The printed color is different from the actual color, the color card shall prevail, the above color is for reference only.